Complete Guide to NOx Sensor Diagnosis and Repair on Diesel Trucks

Modern diesel trucks come equipped with sophisticated emission control systems that can cause headaches for owners when they malfunction. If you're dealing with a P11DB knock sensor performance code on your diesel truck, you're not alone. This comprehensive guide will walk you through understanding NOx sensors, diagnosing problems, and performing repairs correctly.

What is a NOx Sensor and Why Does It Matter?

Understanding NOx Emissions

NOx stands for oxides of nitrogen, which are harmful pollutants that contribute to smog, acid rain, and various health issues including cancer. Diesel engines naturally produce higher NOx emissions compared to gasoline engines, despite having better fuel economy and lower hydrocarbon and carbon monoxide emissions.

The Role of NOx Sensors in Emission Control

NOx sensors are critical components in your truck’s Selective Catalytic Reduction (SCR) system. These sensors monitor nitrogen oxide levels both before and after the SCR catalyst to ensure proper emission control. When a NOx sensor fails, it can trigger error codes like P11DB and potentially put your truck into derate mode.

Understanding the SCR System: How It Works

What is SCR?

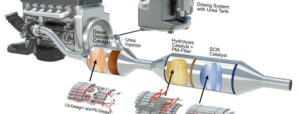

Selective Catalytic Reduction (SCR) is a pollution control technology that reduces NOx emissions in diesel vehicles. The system works in conjunction with the EGR (Exhaust Gas Recirculation) system to dramatically reduce NOx output from your truck’s tailpipe.

SCR System Components

The SCR system consists of several key components:

- NOx Sensor 1 (Upstream): Located near the engine, this sensor reads NOx emissions coming directly from the engine

- DEF Injection Module: Controls the amount of Diesel Exhaust Fluid injected into the exhaust stream

- SCR Catalyst: The large canister where DEF interacts with exhaust gases to reduce NOx levels

- NOx Sensor 2 (Downstream): Monitors NOx levels exiting the tailpipe after treatment

How the System Functions

The upstream NOx sensor sends data to a frame-mounted module, which communicates with both the DEF injection controller and the engine control module. Based on this information, the system calculates the precise amount of DEF needed to achieve optimal NOx reduction in the SCR catalyst.

The Consequences of NOx Sensor Failure: Understanding Derate

What is Derate?

Derate is a protective measure that limits your truck’s performance when emission levels exceed acceptable limits. This system progressively restricts your vehicle’s top speed to encourage immediate repairs.

Derate Progression

The derate system works in stages

- First warning: 100 miles until 65 mph speed limit

- Second warning: 100 miles until 55 mph speed limit

- Final stage: Top speed reduced to 4 mph

This is why running out of DEF or having faulty emission components can leave you stranded with an essentially undriveable truck.

Diagnosing NOx Sensor Problems

Reading the Data Stream

A failing NOx sensor typically produces erratic readings that don’t correlate properly with throttle input. During consistent acceleration, NOx sensor readings should be relatively stable. Wildly fluctuating readings often indicate sensor failure.

Limitations of DIY Diagnosis

Unlike many automotive sensors, NOx sensors use complex multiplexing technology that makes traditional testing methods ineffective. These sensors send square wave data signals over network wires shared with multiple components, requiring specialized equipment like oscilloscopes for proper diagnosis.

Quick Field Test Method

For DIYers without professional diagnostic equipment, there’s a simple field test:

- Remove the NOx sensor from the exhaust pipe

- Turn the ignition on (sensor will heat up due to internal heater)

- Spray the sensor with ammonia-based glass cleaner

- Monitor the data stream on your scan tool for sensor response

This method can help determine if the sensor is capable of reading changes in NOx levels.

Common Causes of NOx Sensor Failure

Contamination Issues

Several factors can contaminate and damage NOx sensors:

- Water contamination: A natural byproduct of combustion

- Fuel contamination: Can occur from incomplete combustion

- Oil contamination: Results from normal engine operation and oil consumption

- Soot buildup: Another natural combustion byproduct

Exhaust System Problems

Exhaust leaks can affect sensor readings by allowing outside air to enter the system, skewing the NOx measurements and potentially causing false readings.

NOx Sensor Replacement Process

Tools and Considerations

Standard O2 sensor socket sets available on Amazon are often inadequate for NOx sensor removal. The thin walls and slots in cheap sockets can cause them to stretch and round off sensor hex surfaces. Professional-grade tools or alternative removal methods may be necessary.

Replacement Steps

- Remove the sensing element: Located in the exhaust pipe

- Replace the processing module: The frame-mounted module that interprets sensor signals

- Reset sensor values: Use a scan tool to calibrate the new sensor

Importance of OEM Parts

Always use OEM sensors rather than aftermarket alternatives. The small cost difference between OEM and aftermarket sensors ($50-100) is insignificant compared to potential towing costs and the inconvenience of premature failure.

Post-Replacement Procedures

ECM Reset Requirements

After installing a new NOx sensor, you must reset the sensor values in the Engine Control Module. This process tells the computer to establish a new zero baseline for the replacement sensor, ensuring accurate readings and proper system operation.

Verification Testing

After replacement and calibration, test drive the vehicle while monitoring both upstream and downstream NOx sensor readings. Properly functioning sensors should show:

- Consistent upstream readings during steady throttle input

- Lower downstream readings indicating effective NOx reduction

Prevention and Maintenance Tips

Fuel Treatment

Regular fuel treatment can help prevent some emission system problems:

- Use quality fuel additives like Stanadyne, Hot Shot’s Secret, or Archoil

- These products increase fuel lubricity and cetane rating

- Higher cetane promotes cleaner combustion, reducing DPF regeneration frequency

Realistic Expectations

Even with proper maintenance, emission system failures are common on diesel trucks. Most Colorado diesels experience some form of emission system problem (DEF injectors, NOx sensors, particulate matter sensors, DEF pumps, or heaters) before reaching 150,000-200,000 miles.

Legal Considerations: Why Deletion Isn’t the Answer

Federal Regulations

Removing or tampering with emission control equipment on a road-going diesel vehicle is a federal crime and felony offense. This applies regardless of the vehicle’s use or your personal situation.

Alternative Solutions

Rather than illegal modifications, focus on:

- Understanding how the systems work

- Proper maintenance and fuel treatment

- Using quality OEM replacement parts

- Working with knowledgeable technicians

Cost Considerations

Typical Repair Costs

| Repair Item | Estimated Cost |

|---|---|

| NOx sensors for Colorado | Approximately $200 |

| NOx sensors for other diesel platforms | $400–$500 |

| Labor costs | Vary by location and complexity |

Long-term Ownership Planning

Factor emission system repairs into your diesel truck ownership budget. These sophisticated systems require periodic attention and component replacement as normal maintenance items.

Conclusion

NOx sensor failures are an unfortunate reality of modern diesel truck ownership. While these systems are complex, understanding their operation helps you make informed decisions about repairs and maintenance. By using quality parts, proper diagnostic procedures, and following legal repair methods, you can maintain your truck’s emission compliance while ensuring reliable operation.

Remember that emission control systems, while sometimes frustrating, serve an important environmental purpose. With proper care and maintenance, these systems can provide years of trouble-free operation while keeping your diesel truck running clean and legal.